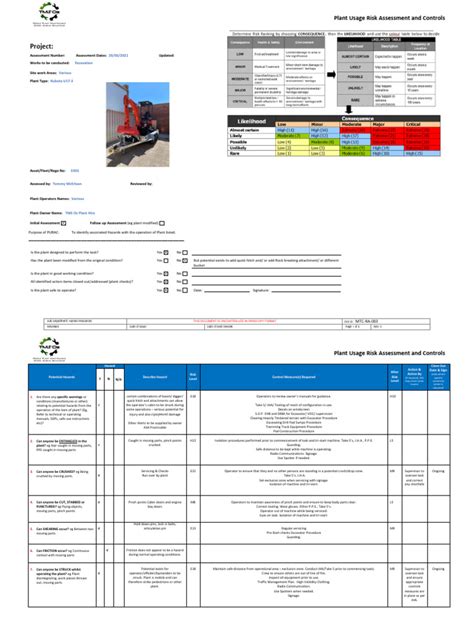

mini digger risk assessment Identify the Hazards and Risk Controls For each of the following HAZARD CATEGORY sections: Check the box for each hazard that you identify for the plant; Apply a risk rating based on the Risk Matrix In the comments box, describe what the hazards are and the consequences; Doosan Infracore North America is breaking the final ties with former sister company Doosan Bobcat with a new line of compact excavators for the U.S. in 2022. Four models, ranging from 2.7 to 5.5.

0 · risk assessment for tlb

1 · plant risk assessment excavator

2 · excavator sop

3 · excavator risk assessment template

4 · excavator operator evaluation form

5 · excavator hazards and controls

The Compaction Drum Roller utilises an excavator track roller as their bearing system and is relatively easy to manufacture. This is why we see many of them imported from high volume manufacturers in Asia. Limitations of the Roller. Due to the drum in the compaction roller system, the Roller has reduced material penetration over the wheel type .COMPACTON WHEEL BEARING REPLACEMENTWatch us replace a bearing on a compactor from start-to-end. Waggoner Welding is a family-owned business with over 20 year.

risk assessment for tlb

Identify the Hazards and Risk Controls For each of the following HAZARD CATEGORY sections: Check the box for each hazard that you identify for the plant; Apply a risk rating based on the Risk Matrix In the comments box, describe what the hazards are and the consequences;Operate the digger in a safe controlled manner, only in areas designated and in good lighting conditions only. Sound horn before emerging from behind a blind corner and reduce speed to .All OHS, Environmental & Quality risks associated with plant operating on projects & workplaces must be assessed & have controls allocated in accordance with the Hierarchy of Control in this .This Mini Digger Risk Assessment has been created to assess the risks associated with the use of mini diggers. The Mini Digger Risk Assessment will give you a good indication of the .

Recognise the hazards, risks and controls required to eliminate or reduce hazards in your workplace from the use of Digger/Excavator. Create awareness about the risks from crushing, .If the Mini Excavator is to be operated in a dangerous or hostile environment, the user/client is responsible for conducting an appropriate risk analysis and applying suitable controls to .

mini excavator 6 bucket

Excavator risk assessment templates are used to identify and assess the risks of excavators. The primary goal is to protect workers from injury or illness through effective .Apply a risk rating based on the Risk Matrix. In the comments box, describe what the hazards are and the consequences; Specify the risk control type from the hierarchy of control at right, for .The instructions recommended within this document apply to normal risk conditions. If the machine is to be operated in a dangerous or hostile environment, the user/client is responsible .carry out risk assessments and provide their employees with clear and appropriate information on any risks that exist in the workplace and how they intend to reduce those risks

Identify the Hazards and Risk Controls For each of the following HAZARD CATEGORY sections: Check the box for each hazard that you identify for the plant; Apply a risk rating based on the Risk Matrix In the comments box, describe what the hazards are and the consequences;Operate the digger in a safe controlled manner, only in areas designated and in good lighting conditions only. Sound horn before emerging from behind a blind corner and reduce speed to an appropriate level.

All OHS, Environmental & Quality risks associated with plant operating on projects & workplaces must be assessed & have controls allocated in accordance with the Hierarchy of Control in this Plant Risk Assessment.This Mini Digger Risk Assessment has been created to assess the risks associated with the use of mini diggers. The Mini Digger Risk Assessment will give you a good indication of the hazards associated with the activity, along with the risks and controls you should be thinking about.Recognise the hazards, risks and controls required to eliminate or reduce hazards in your workplace from the use of Digger/Excavator. Create awareness about the risks from crushing, striking, noise, exhaust fumes, vibration, underground services and more.If the Mini Excavator is to be operated in a dangerous or hostile environment, the user/client is responsible for conducting an appropriate risk analysis and applying suitable controls to mitigate those additional risks. This instruction should be read in conjunction with the Risk Assessment. GENERAL SAFETY.

Excavator risk assessment templates are used to identify and assess the risks of excavators. The primary goal is to protect workers from injury or illness through effective hazard identification and risk assessment processes.

Apply a risk rating based on the Risk Matrix. In the comments box, describe what the hazards are and the consequences; Specify the risk control type from the hierarchy of control at right, for each current or proposed risk control; Explain what controls will be put in place for the hazard in CONTROL DESCRIPTION.

The instructions recommended within this document apply to normal risk conditions. If the machine is to be operated in a dangerous or hostile environment, the user/client is responsible for conducting an appropriate risk analysis and applying suitable controls to .carry out risk assessments and provide their employees with clear and appropriate information on any risks that exist in the workplace and how they intend to reduce those risksIdentify the Hazards and Risk Controls For each of the following HAZARD CATEGORY sections: Check the box for each hazard that you identify for the plant; Apply a risk rating based on the Risk Matrix In the comments box, describe what the hazards are and the consequences;

plant risk assessment excavator

Operate the digger in a safe controlled manner, only in areas designated and in good lighting conditions only. Sound horn before emerging from behind a blind corner and reduce speed to an appropriate level.All OHS, Environmental & Quality risks associated with plant operating on projects & workplaces must be assessed & have controls allocated in accordance with the Hierarchy of Control in this Plant Risk Assessment.

This Mini Digger Risk Assessment has been created to assess the risks associated with the use of mini diggers. The Mini Digger Risk Assessment will give you a good indication of the hazards associated with the activity, along with the risks and controls you should be thinking about.Recognise the hazards, risks and controls required to eliminate or reduce hazards in your workplace from the use of Digger/Excavator. Create awareness about the risks from crushing, striking, noise, exhaust fumes, vibration, underground services and more.If the Mini Excavator is to be operated in a dangerous or hostile environment, the user/client is responsible for conducting an appropriate risk analysis and applying suitable controls to mitigate those additional risks. This instruction should be read in conjunction with the Risk Assessment. GENERAL SAFETY. Excavator risk assessment templates are used to identify and assess the risks of excavators. The primary goal is to protect workers from injury or illness through effective hazard identification and risk assessment processes.

Apply a risk rating based on the Risk Matrix. In the comments box, describe what the hazards are and the consequences; Specify the risk control type from the hierarchy of control at right, for each current or proposed risk control; Explain what controls will be put in place for the hazard in CONTROL DESCRIPTION.The instructions recommended within this document apply to normal risk conditions. If the machine is to be operated in a dangerous or hostile environment, the user/client is responsible for conducting an appropriate risk analysis and applying suitable controls to .

excavator sop

excavator risk assessment template

2022 BOBCAT, E10 Excavators - Mini (up to 12,000 lbs), Battery Powered E10 Mini Excavator with Charger. Designed to be able to go through a 1 man door

mini digger risk assessment|excavator risk assessment template