compacting soil with excavator A compactor is a device that compresses dirt, soil or gravel to create a stable surface for construction or landscaping. Learn about 15 types of compactors, such as rammers, plates and rollers, and how to choose the right one for your project.

We only do self-Drive Hire. We run Excavators all over Ireland Call 086 2440276 for your machinery quote today!!

0 · Soil Compaction Equipment

1 · Soil Compaction

2 · How to Compact Soil After Excavation: Your Step

3 · Different Types of Soil Compaction Equipment: Types of Rollers

We supply a full range of excavators in the High-Peak area, including micro diggers, mini .

Learn about different types of rollers and other soil compaction equipments for various soil types and moisture conditions. Find out how rammers, vibrating plate compactors, vibro tampers, smooth wheeled rollers, sheepsfoot rollers and pneumatic tyred rollers work.

mini excavator rental with mulching head

Learn about different types of rollers and other soil compaction equipments for various soil types and moisture conditions. Find out how rammers, vibrating plate compactors, vibro tampers, smooth wheeled rollers, sheepsfoot rollers and pneumatic tyred rollers work. Compaction after excavation is the process of pressing down loosened soil to eliminate air pockets and increase soil density. This ensures that the ground can support structures and prevents future issues like settling, erosion, or water pooling.The following steps outline the general process for compacting soil in these projects: Excavation: Remove any topsoil, vegetation, or debris to expose the subgrade soil. The depth of excavation depends on the thickness of the paving material and the required sub-base and base layers.

Soil Compaction Equipment

Learn about different types of soil compaction equipment, such as rammers, vibratory compactors, rollers and more. Find out how to select the right equipment for your project based on the type of soil, area and force required. A compactor is a device that compresses dirt, soil or gravel to create a stable surface for construction or landscaping. Learn about 15 types of compactors, such as rammers, plates and rollers, and how to choose the right one for your project.

Learn how to choose the right equipment for different types of soils and job sites. Compare rammers, plate compactors, and trench rollers based on soil characteristics, size, and vibration. There are three types of compaction equipment: static, vibratory, and impact, points out Hoffman. Static rollers come in three-wheeled, tandem, or pneumatic-tired designs and rely on the weight of the drum and machine to compact material. They work best for compacting thin layers of soil or asphalt. Learn about four primary types of compaction equipment: smooth drum, padfoot, tandem and combination rollers. Each type has unique features and applications for different soil types and.There are three main categories of plate compactors: a single plate compactor, a reversible plate compactor, and a high performance/heavy-duty plate compactor. Single plate compactors go in a forward direction only, and are probably the most popular choice for smaller asphalt jobs.

Soil Compaction

How to Compact Soil After Excavation: Your Step

Soil compaction is a fundamental aspect of construction and landscaping projects, requiring precise techniques and dependable equipment. Our comprehensive guide has provided the insights you need to master soil compaction, from equipment selection to best practices and expert tips for success.

Learn about different types of rollers and other soil compaction equipments for various soil types and moisture conditions. Find out how rammers, vibrating plate compactors, vibro tampers, smooth wheeled rollers, sheepsfoot rollers and pneumatic tyred rollers work.

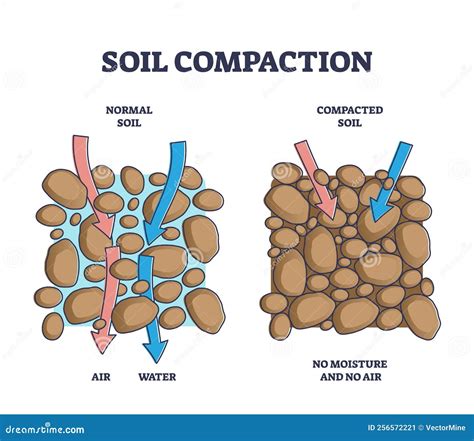

Compaction after excavation is the process of pressing down loosened soil to eliminate air pockets and increase soil density. This ensures that the ground can support structures and prevents future issues like settling, erosion, or water pooling.

The following steps outline the general process for compacting soil in these projects: Excavation: Remove any topsoil, vegetation, or debris to expose the subgrade soil. The depth of excavation depends on the thickness of the paving material and the required sub-base and base layers. Learn about different types of soil compaction equipment, such as rammers, vibratory compactors, rollers and more. Find out how to select the right equipment for your project based on the type of soil, area and force required. A compactor is a device that compresses dirt, soil or gravel to create a stable surface for construction or landscaping. Learn about 15 types of compactors, such as rammers, plates and rollers, and how to choose the right one for your project. Learn how to choose the right equipment for different types of soils and job sites. Compare rammers, plate compactors, and trench rollers based on soil characteristics, size, and vibration.

There are three types of compaction equipment: static, vibratory, and impact, points out Hoffman. Static rollers come in three-wheeled, tandem, or pneumatic-tired designs and rely on the weight of the drum and machine to compact material. They work best for compacting thin layers of soil or asphalt. Learn about four primary types of compaction equipment: smooth drum, padfoot, tandem and combination rollers. Each type has unique features and applications for different soil types and.

There are three main categories of plate compactors: a single plate compactor, a reversible plate compactor, and a high performance/heavy-duty plate compactor. Single plate compactors go in a forward direction only, and are probably the most popular choice for smaller asphalt jobs.

Different Types of Soil Compaction Equipment: Types of Rollers

Mini digger rentals are Macs Digger Hire Hampshire's specialty in Gosport and the surrounding areas. We offer small excavators and compact diggers for modest operations that need restricted access. Renting one of our mini diggers is a very economical and useful option for clients in the residential and commercial sectors.

compacting soil with excavator|Different Types of Soil Compaction Equipment: Types of Rollers